Quick Summary: Are you running out of stock, spending too much, or guessing demand wrong? This is why AI in inventory management is better with smarter forecasts, real-time tracking, and automated decisions. In this guide, we’ll examine how it works, its main benefits, and how companies like Amazon, Starbucks, and Zara are already utilizing it to stay ahead.

Inventory management has been the backbone of successful businesses across retailers, manufacturers, e-commerce stores, and even logistics providers. How well you balance supply and demand will directly impact the profitability, customer satisfaction, and growth of your business. However, traditional methods such as manual checks, static spreadsheets, and legacy ERP systems often struggle to keep pace with today’s complex, highly dynamic, and uncertain markets.

This is where AI in inventory management is stepping in. It combines new-age technologies and capabilities, such as machine learning, computer vision, predictive analytics, and automation, to enhance the existing inventory management software and solutions. AI-driven systems can help businesses relying on traditional inventory management systems take a more proactive and data-driven approach to stock management and make informed decisions.

The result? Smarter forecasting, real-time visibility improvements, optimized storage, and smart restocking that cuts down the costs and strengthens resilience across the supply chain. Today, we will explore how artificial intelligence in inventory management is revolutionizing modern business operations, the technologies behind it, and the benefits of AI in inventory management, with real-world examples from companies like Amazon and Walmart, that prove AI is no longer optional but the future of inventory management.

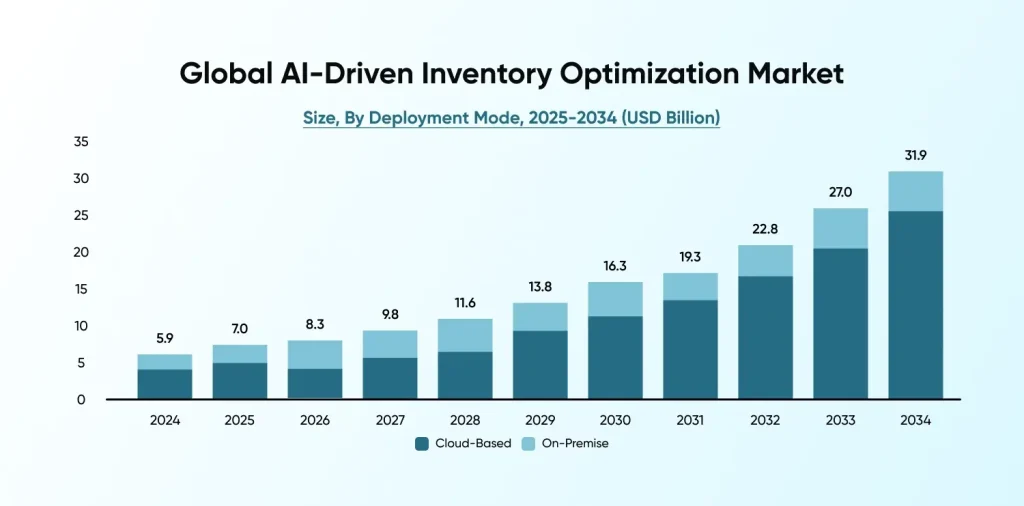

The Global AI-Driven Inventory Optimization Market Size

The global market for AI in inventory optimization is experiencing impressive growth. With a predicted market size of $31.9 billion in 2034, growing at a CAGR of 18.3% from 2025 to 2034. The primary reason behind this surge is the adoption of AI-powered inventory management in industries such as retail, manufacturing, and logistics.

8 Core Capabilities of AI in Inventory Management

1. Effortless Demand Forecasting:

AI-powered demand forecasting provides a precise view of future needs. It analyzes vast amounts of data points, including historical sales and economic trends. It also takes into consideration the sentiment on social media. AI in inventory management for demand forecasting accurately predicts demand through proper calculations, minimizing costly overstocking. It also prevents damaging stockouts and misses out on potential sales. All decisions and planning related to inventory management become scientifically backed, rather than based on guesswork.

2. Real-Time Inventory Tracking:

When you combine AI and IoT for inventory management, you make the perfect recipe for automating and optimizing the entire inventory cycle from warehouses to stores. It eliminates any dark spots in the supply chain. Every team member has access to accurate, up-to-the-minute data.

3. Automated Reordering/Replenishment:

One of the biggest benefits of AI in inventory management is the time and effort it saves for mundane yet important inventory tasks. Based on forecasts, it calculates optimal reorder points by considering supplier lead times. The system can be fine-tuned to ensure stock is available when needed. Such automation takes a significant workload off the staff’s shoulders, freeing them up for more strategic work. It really makes order replenishment prices cost-effective and straightforward.

4. Optimized Smart Warehousing:

Utilizing AI for inventory management and warehouse optimization yields more intelligent warehousing solutions. It analyzes product popularity and order patterns to determine the most logical, optimal, and efficient placement for a particular product. It even helps transport teams by calculating the fastest picking routes. This results in a greduction in labor costs and retrieval times, thereby maximizing order fulfillment efficiency.

5. Dynamic Safety Stock Optimization:

AI systems continually adjust safety stock levels. They hire AI developers to create an advanced inventory management system that calculates demand volatility and supplier reliability. This reduces the instances of overstocking while still maintaining a buffer for sudden surges or spikes.

6. Supply Chain Optimization:

AI provides a complete view of the supply chain operations. It can be optimized for various “what-if” situations, helping companies navigate disruptions. The role of AI in supply chain management is to build a more resilient supply chain that can quickly adapt to changes.

7. Inventory Segmentation:

One of the most important activities in inventory management is smart segmentation. It is a perfect use case for artificial intelligence in inventory management, as it is based on metrics such as sales velocity and profitability to suggest a tailored stocking strategy. High-value items can be managed differently, optimizing resource allocation, resulting in improved overall inventory performance.

8. Anomaly Detection:

If you want to tighten security and reduce the chances of error in your warehouse management system, AI can be a valuable asset. It is trained on extensive sets of relevant data to identify what constitutes “normal.” It can instantly flag any deviation from those parameters, which gives an early warning system.

How AI-Based Inventory Management Works: Key Technologies Explained

| Technology | Description | Practical Examples |

| Machine Learning Algorithms | Learn from historical and real-time data to identify patterns and make predictions. | Optimizing reorder points, detecting seasonal demand shifts, adjusting pricing. |

| Predictive Analytics | Uses statistical models and ML techniques to forecast future inventory needs. | Forecasting demand spikes during holidays, planning warehouse capacity. |

| Computer Vision | Enables AI to “see” and track inventory in physical spaces, automating manual processes. | Automated shelf scanning in retail, real-time stock level monitoring via cameras. |

| Deep Learning | Handles complex, non-linear relationships in data to improve demand accuracy. | Predicting consumer buying trends across regions, managing multi-channel demand. |

What are the Benefits of AI in Inventory Management?

- Demand Forecasting: AI-based forecasting analyzes data on sales history, market trends, and seasonal patterns to generate data-driven insights.

- Real-Time Tracking: It provides visibility into stock levels, helping to avoid overstocking and stockouts.

- Automated Reordering: AI systems can trigger a purchase order automatically when inventory hits an expected threshold

- Reduced Carrying Costs: Improved smarter stock control that lowers storage costs and frees up working capital.

- Better Supply Chain Decisions: AI identifies bottlenecks and recommends faster and cost-effective routes or suppliers.

- Cost Reduction: By reducing overstocking and optimizing shipping, companies can lead to substantial savings.

- Improved Accuracy and Efficiency: AI and inventory management reduce human error, leading to more accurate stock counts and faster fulfillment.

How Leading Companies Use Artificial Intelligence in Inventory Management?

Amazon: Predictive Inventory and Autonomous Robotics

Amazon is also recognized for its AI-driven inventory management efforts and successes. It utilizes Artificial Intelligence to forecast product demand and optimize warehouse operations. Their AI inventory management system utilizes machine learning algorithms to adjust stock levels, streamline fulfillment, and minimize delays.

Innovations from Amazon Towards AI in Inventory Management

| AI Innovation | Function / Benefit |

| Generative AI Mapping (Wellspring) | Accurately identifies building entrances, parking spots, and shared mailrooms, improving delivery precision. |

| AI-Powered Demand Forecasting | Predicts what products customers want, where, and when, ensuring optimal inventory placement across warehouses. |

| Agentic AI for Robotics | Robots understand natural language commands, perform multiple tasks autonomously, and support employees by handling repetitive or heavy-lifting work. |

Starbucks: AI-Driven Inventory Counting

Starbucks also uses AI for inventory management across thousands of stores in North America to ensure their popular products like oat milk, cold foam, and caramel drizzle are always available. Their AI inventory management system combines computer vision with 3D spatial intelligence and augments reality for delivering faster and accurate counts.

Benefits of AI in Inventory Management for Starbucks:

- Faster, more frequent counts: Inventory is checked eight times more often than before.

- Real-time visibility: Low-stock items are flagged instantly, enabling quicker replenishment.

- Smarter operations: Reduces manual work for partners, letting them focus on craft and customer connection.

Zara: Demand Forecasting and Inventory Optimization

Zara uses AI and inventory management to run a professional supply chain that monitors real-time data, predicts customer demand, and dynamically optimizes stock levels. This AI-based inventory management system enables the frequent introduction of new designs in as little as a week. This reduces the risk of overstock and stockouts.

- Faster product turnaround: New designs go from concept to store in 1 week versus the industry average of 3–6 months.

- Reduced inventory costs: Overstocks and stockouts are significantly minimized.

- Improved customer satisfaction: Products are available when and where customers want them.

- Sustainable operations: Waste is reduced through smarter inventory planning.

Lowe’s: AI-Powered Retail Operations

Lowe is a prime AI in inventory example of how AI can modernize traditional stores through the use of inventory management systems. These AI-powered systems forecast demand, track inventory, and optimize checkout processes. As a result, they also improve service delivery. Lowe’s implementation shows the practical benefits of AI in inventory management, including efficiency gains and enhanced customer experience.

- Digital twins & planograms: Optimize store layouts and inventory placement.

- GenAI associate advisor: Supports store associates in delivering a superior customer experience.

- Computer vision: Prevents inventory shrinkage and speeds up checkout.

- Operational efficiency: Faster replenishment and better stock visibility across stores.

Challenges of Implementing AI in Inventory Management (and How to Overcome Them)

The role of AI in digital transformation of inventory management is now evident. However, it doesn’t come without its challenges. If you are planning to implement AI based inventory management, here are the challenges you need to look out for, with their practical turnarounds:

Data Privacy

What does an AI system rely on for working its magic? Data. Hence, it becomes the first and foremost priority and an area of concern for integrating AI in your inventory management system. Data and AI transform businesses if the right data protection standards, protocols, and best practices are followed. Effective strategies to manage data-related challenges include:

- Enforce robust access controls: Restrict access to and control over viewing or changing sensitive customer and inventory data.

- Use data encryption: Protect data while at rest and in transit, thus avoiding unauthorized access

- Adhere to regulatory requirements: Adjust to GDPR, CCPA, or other local data protection laws.

- Anonymize and aggregate data: Reduce privacy threats while still ensuring correct AI predictions.

- Track and audit data usage: Continuously inspect how AI systems access and process data to ensure accountability and transparency.

Operational Accountability

There are many situations where algorithms will simply be unable to handle the complexity and volume of information. This doesn’t mean that artificial intelligence in inventory management is not good enough. The problem often lies in the market’s rush to implement AI in inventory management.

Every business rushes to implement and adapt this technology without doing its due diligence. A proper AI implementation requires reaching out to a professional AI consulting services provider, examining the level of AI involvement needed by your company, and crafting a custom AI software solution that addresses your needs, without overdoing it.

Data Fragmentation

Most traditional inventory systems are likely not to have all their data cleaned, processed, or stored in a centralized location. Hence, to create a truly well-functioning AI model, you would need to take help from a professional AI software development services company that is well-versed in data integration, standardization, and other related activities.

Smooth Integration with Existing ERP Systems

Inventory management systems are not something you should change frequently; they need to be reliable, secure, and long-lasting. Traditional ERP systems may not have provision for APIs or real-time data processing. Complex integration requirements can be both costly and time-consuming. For such situations, it is crucial to invest in scalable AI-based inventory management solutions developed by professional AI and data engineers.

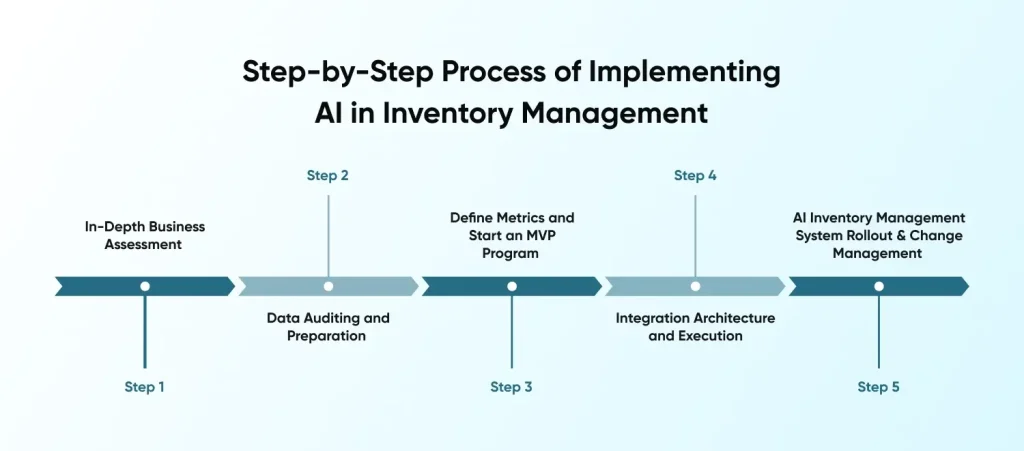

Step-by-Step Process of Implementing AI in Inventory Management

Want to build your AI-driven warehouse management system? Well, a successful implementation of inventory management with AI requires careful planning, strategy building, and ensuring proper ROI on the effort. Here are the logical steps to ensure safe, secure, performant, and accurate integration of AI in inventory management systems:

Step 1: In-Depth Business Assessment:

Before you start the journey of AI in inventory management, make sure to have a proper understanding of your current inventory operations. Implementing a new solution without understanding its purpose will only cost you money, with no returns. Identify the pain points you are facing in your business. Do you frequently experience stockouts, or are you concerned about high carrying costs? Having answers to these questions will form your roadmap for AI in the inventory journey.

Step 2: Data Auditing and Preparation:

Any AI implementation is only as good as the data on which it has been trained. This is a very important step in the process, where data engineers and AI experts audit existing data sources like ERPs, WMS, and sales data, and clean historical data, to ensure data quality and consistency. This phase takes the most time as it creates the base of the AI-driven inventory management system.

Step 3: Define Metrics and Start an MVP Program:

It is always wiser to start with a pilot project instead of committing to a full-scale launch. This involves selecting a well-defined problem, such as optimizing the demand forecast for a specific product. You should have a clear success metric defined for such a task, such as improving forecasting accuracy to 97% or reducing error rate by 15%. Outsource this to a dedicated AI MVP development company that provides the means and expertise to carry out such pilot programs.

Step 4: Integration Architecture and Execution:

This phase involves making design choices of how the new AI inventory management software will integrate with existing platforms. It also needs to have a detailed plan on how the pilot tests will run, and compare AI-driven results with the traditional approach.

Step 5: AI Inventory Management System Roll out and Change Management

After running a successful pilot, the system can be scaled across the organization or changes can be made where needed before committing to the launch. This step also includes training on-premise staff on how to operate the new systems and adapt to a data-driven approach.

What Does the Future of Inventory Management Look Like?

The future of inventory management surely has a reserved spot for AI and innovative technologies that automate, scale, add security, reduce costs, and provide other important benefits. Most reactive traditional approaches to inventory management will take a more proactive approach, reducing delivery time, increasing stock effectiveness, and more. The rapid adoption of AI and IoT in inventory management will also raise questions and concerns about the ethical use and sustainable practices, as AI will play a role in lowering the environmental impact of the industry.

Why Choose CMARIX for AI-driven Inventory Management System Development?

Having the right technology partner is the most crucial step in ensuring a successful AI implementation. At CMARIX, we don’t simply build software; we engineer custom AI inventory management solutions designed to solve your specific challenges.

- Tailored AI for Your Business: We don’t do one-size-fits-all. Every solution is designed to match your goals and the way your business operates.

- Hands-On AI Expertise: From machine learning to computer vision and predictive analytics, our team knows how to build systems that actually work and deliver results.

- Clear and Collaborative Approach: No mystery, no jargon. You stay in the loop with agile processes that keep things flexible and transparent.

- Complete Support, Start to Finish: From strategy and consulting to development and integration, we handle the entire journey so your AI fits seamlessly into your business.

Final Words

If you are looking for a way to integrate AI in inventory management or deciding whether it is ideal for your business, make sure to understand your current pain points, identify areas that can be optimized, and determine how the ROI of such implementation will impact your overall revenues. To figure all of this out, you can simply rely on the help of professional AI consulting services of a trusted AI software development company to guide you through the maze of AI implementation and find the best possible roadmap to your AI inventory success.

FAQs of AI in Inventory Management Systems

How to use AI in Inventory Management?

Hire AI developers who can build and deploy AI-powered demand forecasting tools that can read your sales data, seasonal trends, and market patterns. These systems can automate stock replenishment times, avoid overstocking as well as understocking. Set up automated reorder points that trigger purchases based on AI calculations, rather than relying on guesswork. Use smart analytics dashboards to spot slow-moving inventory and optimize stock levels across all locations.

Why Use AI for Inventory Management in E-Commerce

E-commerce creates massive amounts of data that humans cannot process effectively in real-time. AI analyzes this data to predict customer demand, seasonal spikes, and changes in buying behavior instantly. Traditional methods often result in 20-30% overstock or stockouts, whereas AI significantly reduces these costly mistakes.

What Are the Benefits of AI in Inventory Management?

AI reduces inventory costs by 15-25% while improving product availability by 10-20%. You eliminate human errors in reordering decisions and gain accurate forecasting that considers hundreds of variables simultaneously. Real-time visibility across all sales channels helps you identify dead stock quickly and optimize inventory distribution.

Can AI Integrate With My Current ERP or Supply Chain Management Software?

Most modern AI inventory solutions integrate seamlessly with popular ERP systems, such as SAP, Oracle, NetSuite, and Microsoft Dynamics, through APIs. For more information on this integration, please contact our professional AI consultants today.

What Are the Challenges in Adopting AI for Inventory Operations?

Data quality presents the biggest obstacle since AI needs clean, consistent historical data spanning 12-24 months minimum. Many companies discover their existing data is incomplete or inconsistent during implementation. Staff resistance to new technology and initial setup costs can slow adoption significantly.

What ROI Can Businesses Expect From AI Inventory Solutions?

Most businesses achieve ROI within 6-18 months with typical returns of 200-400% over three years. Small to medium businesses commonly see a 10-20% reduction in inventory costs and 15-30% fewer stockouts. ROI depends heavily on your current inventory processes and data quality.