Quick Summary: Smart, data-driven logistics is redefining how global supply chains operate. By using machine learning in logistics, companies are solving major challenges like inaccurate forecasting, route inefficiencies, and downtime. ML-powered insights cut costs, improve delivery speed, enhance customer satisfaction, and create resilient, sustainable, and future-ready logistics operations.

The global supply chain industry is at a breaking point. Years of unexpected disruptions, from pandemics to geopolitical shifts, have exposed deep fragilities in how goods move around the world. For logistics companies, the pressure is immense. Customers expect cheaper, faster, and more reliable delivery, while operating costs are soaring.

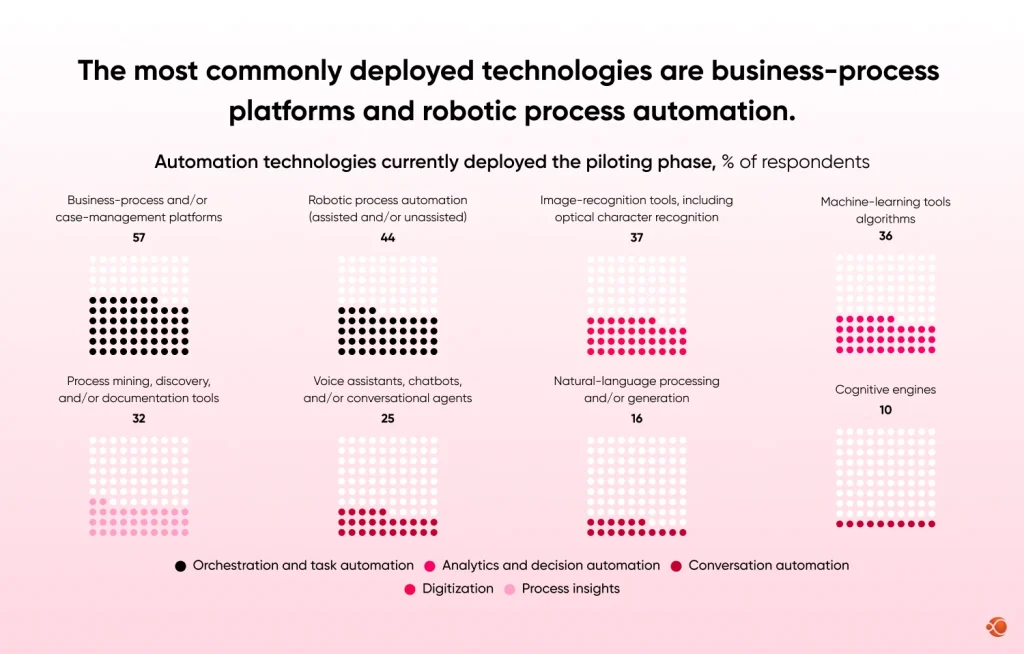

The solution for this isn’t simply working harder; it’s working smarter. The single most powerful tool available to the logistics industry right now is Machine Learning(ML). By moving beyond reactive decision-making and using AI-powered logistics solutions, companies can finally achieve the resilience and efficiency needed to thrive in 2025 and beyond.According to the McKinsey Global Survey Report, 36% of respondents said that ML algorithms are deployed beyond the pilot stage.

This comprehensive guide will explore exactly why ML adoption is crucial for supply chain efficiency, detailing the core challenges it solves, the high-impact use cases, and the practical steps for implementation.

5 Key Logistics & Supply Chain Challenges Solved by Machine Learning

ML is not a simple solution, but a precise, data-driven engine that solves some of the most stubborn and expensive problems in the logistics world.

Solving Inaccurate Demand Forecasting and Inventory Management

Traditional forecasting models (often relying on simple averages or time-series analysis) fail when market conditions change rapidly. Machine Learning for supply chain optimization uses advanced techniques like logistic regression in machine learning to analyze hundreds of variables simultaneously: seasonality, promotional schedules, weather patterns, social media trends, and competitor actions.

This leads to a far more precise prediction of what a customer will buy, when, and where. The result is optimized inventory levels, dramatically reducing both costly stockouts and the capital tied up in slow-moving items.

Optimizing Route Planning to Cut Fuel Costs

For transportation fleets, fuel is one of the largest operating expenses. Standard route planning software often relies on static maps and historical traffic data. Machine Learning in transportation management goes a step further, using predictive analytics in logistics to forecast real-time traffic jams, weather delays, and even driver availability.

ML models calculate the most fuel-efficient routes minute-by-minute, significantly cutting mileage and time spent idling, leading to a substantial decrease in fuel spend and carbon emissions.

Eliminating Warehouse Productivity Bottlenecks with AI

The warehouse floor is always filled with people, equipment, and packages. Bottlenecks like congested sorting areas and slow picking lines are a constant issue. Machine learning in warehouse management uses computer vision and sensor data to monitor workflow in real-time.

It identifies the specific points where delays occur, then automatically adjusts scheduling or reassigns tasks to equipment (like Autonomous Mobile Robots) to maintain a smooth, high-speed flow. This maximizes throughput without requiring additional labor.

Reducing Equipment Downtime and Maintenance Costs

The costs associated with a key sorting machine or a truck breaking down mid-route, failing are enormous, including repair bills, customer dissatisfaction, and delayed shipments. Predictive Maintenance for Logistics and Transportation Fleets leverages ML by analyzing data from vehicle sensors (vibration, temperature, fluid levels) and operational logs.

The model learns to recognize the subtle warning signs that precede a failure. Instead of following a time-based maintenance schedule, the company can service the asset just before it’s about to fail, reducing costly emergency repairs and maximizing the operational life of the equipment.

Minimizing Manual Data Errors in Logistics Operations

From bill of lading entries to customs forms, the logistics process is heavily reliant on accurate data. Manual entry, however, is rife with human error. ML models can be trained to automatically read, verify, and input information from scanned documents and images (using Optical Character Recognition and Natural Language Processing).

This eliminates the administrative time spent on data entry, which reduces error rates and makes sure that the downstream planning systems are working with clean, reliable data. Organizations looking to implement these capabilities often hire AI developers with specific experience in document processing and natural language understanding.

6 High-Impact Machine Learning Use Cases for Logistics Companies

Beyond solving general challenges, specific applications of machine learning in logistics deliver powerful, quantifiable improvements across the entire supply chain.

ML for Demand Forecasting and Inventory Optimization

This is perhaps the most immediate return-on-investment (ROI) use case. By integrating data from marketing campaigns, sales history, and external macroeconomic indicators, ML models produce highly accurate forecasts. This directly enables inventory optimization, ensuring the right items are in the right distribution center at the right time, minimizing working capital and maximizing service levels.

Advanced AI in inventory management platforms can even recommend safety stock levels and optimal reorder points based on supply chain variability and customer demand patterns, turning what was once a manual guessing game into a data-driven science.

Route Optimization and Last-Mile Delivery with Machine Learning

In the delivery process, the most expensive part is the last mile. ML algorithms factor in not just distance, but also delivery time windows, package volume, driver breaks, and real-time traffic to create dynamic, optimized routes. This is a game-changer for cost-efficiency and speed in urban environments.

Warehouse Automation: ML-Powered Picking and Sorting Systems

ML powers the decision-making of automated systems. For example, a picking robot might use machine learning-powered computer vision to quickly identify and safely grasp irregular items. Sorting systems use ML to correctly classify packages, reducing mis-sorts and ensuring parcels reach their correct next destination with minimal delay.

Predictive Maintenance for Logistics and Transportation Fleets

As mentioned, this shifts maintenance from reactive or calendar-based to Predictive Analytics in Logistics. By anticipating failures in high-value assets like trucks, vessels, or specialized warehouse management equipment, companies save on repair costs, avoid operational delays, and increase overall fleet utilization.

Machine Learning for Fraud Detection in Shipping and Freight

Fraud, waste, and abuse in the complex world of shipping can cost companies millions. ML models analyze transactional data patterns such as invoicing, claims, shipping routes, and consignee information, to spot anomalies that indicate fraudulent activity far faster and more reliably than traditional human audits.

Companies seeking to implement these sophisticated detection systems often partner with Machine Learning app development services providers who specialize in anomaly detection algorithms and can customize solutions for specific fraud patterns common in the logistics sector.

Supplier Risk Assessment and Management using Machine Learning

Supply chain risks extend far beyond the physical movement of goods. ML models can analyze public information, financial data, news feeds, and geopolitical indicators to assess the reliability and stability of key suppliers. This allows logistics firms to find alternative suppliers before a risk event occurs, dramatically improving supply chain resilience.

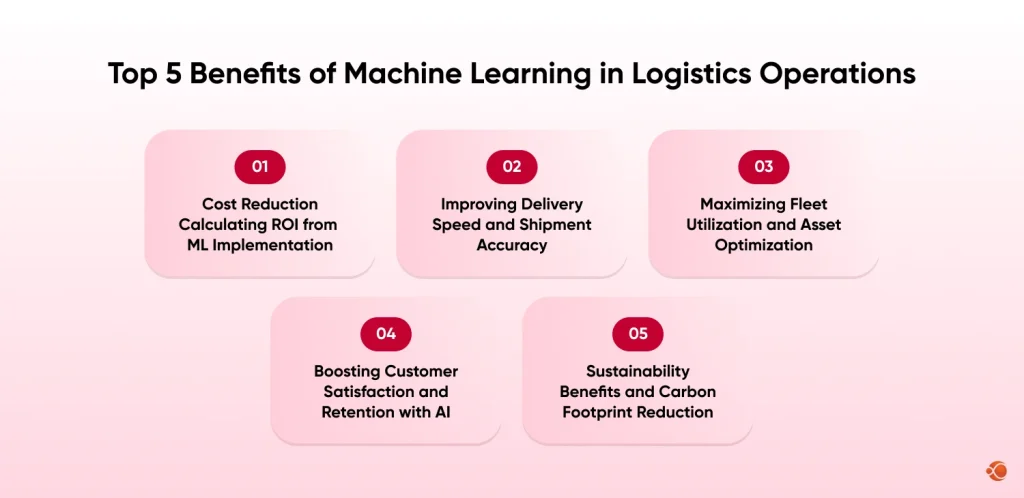

Top 5 Benefits of Machine Learning in Logistics Operations

The collective power of these ML applications results in several fundamental benefits of machine learning in logistics operations.

Cost Reduction: Calculating ROI from ML Implementation

The cost savings are immediate and measurable. Optimized routes reduce fuel and labor costs. Predictive maintenance minimizes expensive downtime. Accurate forecasting reduces inventory holding costs and obsolescence. For many companies, the ROI from the first few ML projects can pay for the entire implementation within a year.

Improving Delivery Speed and Shipment Accuracy

ML-optimized processes from forecasting and inventory placement to last-mile routing all converge to increase the speed of delivery. Furthermore, the minimization of manual data errors and fraud means fewer misshipped packages or fewer delays, leading to higher shipment accuracy.

Companies that invest in logistics app development can provide drivers and warehouse staff with real-time ML insights directly on their mobile devices, eliminating delays caused by outdated information.

Maximizing Fleet Utilization and Asset Optimization

By predicting maintenance needs and optimizing dispatch scheduling, ML ensures that every truck, forklift, and container is being used to its maximum potential. Less time sitting idle or in unplanned repair means a higher return on capital assets.

Boosting Customer Satisfaction and Retention with AI

In the end, customers care about two things: getting their shipment when they expect it, and getting clear communication. AI-Powered logistics solutions allow companies to provide highly accurate, real-time estimated times of arrival (ETAs) and proactive updates about any potential delays, massively boosting trust and customer loyalty.

Sustainability Benefits and Carbon Footprint Reduction

Every consolidated shipment, route, and reduction in unplanned asset downtime contributes to less fuel consumption and fewer wasted resources. ML has become a powerful tool for achieving corporate sustainability goals and reducing carbon footprint.

ML Implementation in Logistics: A 6-Phase Framework

Phase 1: Data Assessment and Infrastructure Preparation

The foundation of any successful machine learning(ML) project is clean, accessible data. This phase includes auditing existing data sources, integrating disparate systems, and building a scalable data infrastructure that can feed the ML models reliably.

Phase 2: Identifying High-Impact ML Use Cases

Don’t try to solve everything at once. Begin by focusing on areas where the business pain is highest and the available data is best. High-impact candidates usually include demand forecasting, route optimization, or predictive maintenance.

Phase 3: Build vs. Buy: Choosing Your ML Strategy

Should you build custom models with an in-house data science team, or buy off-the-shelf software with embedded ML capabilities? The “buy” option is often faster for standard problems, while “build” is necessary for highly unique operational challenges.

Organizations considering the build approach should evaluate whether to hire AI developers with logistics domain expertise or upskill their existing technical teams through targeted training programs.

Phase 4: Running a Successful ML Pilot Project

Start with something small. Apply the ML model to a single, contained region, a specific product line, or one warehouse. A pilot project allows the team to test the model’s performance, gather user feedback, and refine the process without disrupting the core business.

Phase 5: Measuring ROI and Core Performance Metrics

The success of the pilot must be proven with clear metrics. For route optimization, this might be a percent reduction in fuel costs. For forecasting, it’s the percent reduction in forecast error. Clear, measurable success metrics justify the next stage of investment.

Phase 6: Scaling ML Across Logistics & Supply Chain

Once the pilot is proven, the models and processes are deployed across the broader business. This requires training teams on new workflows, change management, and continually refining the models as more data becomes available.

Machine Learning in Logistics: Detailed Cost and ROI Analysis

Understanding the financial implications is crucial for securing executive buy-in. While costs vary widely, a structured approach helps justify the investment.

| Category | Typical ROI Timeline / Insight | Key Components |

| Initial Investment | High upfront cost, but important for building a strong base | Setting up machine learning(ML) tools, data infrastructure, and hiring skilled teams |

| Ongoing Costs | Moderate recurring cost that make sure consistency and model reliability | Model retraining, cloud computing, and system integration with the logistics system |

| Demand Forecasting | 6–12 months ROI | Inventory losses and reduces stockout |

| Route Optimization | 3–6 months ROI | Reduces labor costs and lowers fuel use |

| Predictive Maintenance | 12–18 months ROI | Cuts downtime expenses and emergency repair |

| Business Case Focus | Strengthens ROI justification and executive approval | Quantify existing inefficiencies and project measurable savings |

Building a Business Case for Logistics ML Investment

To develop a compelling business case, quantify the savings from the operational challenges. For instance, calculate the annual cost of an inaccurate forecasting error. This concrete financial modeling is what secures the necessary capital.

Best Practices for Logistics Companies Deploying Machine Learning

Successful ML implementation in logistics isn’t just about the technology; it’s about organizational strategy and its execution.

Starting with Focused, High-Value ML Projects

A focused project that delivers a guaranteed $1 million in savings is better than a massive, sprawling initiative that delivers an uncertain outcome. Solve one clear, painful problem first to build internal momentum and expertise.

Building Data Infrastructure Before Model Deployment

ML models are only as good as the data they consume. Rushing to deploy a model on messy, siloed data guarantees failure. Invest in building data infrastructure and data governance practices first to ensure clean, reliable data feeds.

Establishing Cross-Functional ML Teams

An ML project isn’t just for the IT department. It requires collaboration between data scientists, operations managers who understand the daily realities of logistics, and finance personnel who can track the ROI. Organizations that lack in-house ML expertise often partner with providers offering comprehensive artificial intelligence development services to supplement their teams and accelerate implementation timelines.

Setting Realistic Stakeholder Expectations

ML results are not instantaneous. Models require time to learn and for data to accumulate. Communicate realistic timelines and expected accuracy levels to management to avoid disappointment and make sure sustained support.

Establishing Model Monitoring and Retraining Schedules

Market conditions change, and a model trained on last year’s data may become irrelevant. Models must be continuously monitored for “drift” and retrained periodically on the latest data to maintain peak accuracy and effectiveness.

Future of Machine Learning in the Logistics Industry: Trends & Predictions

The role of machine learning in logistics and supply chain is set to grow even more dramatically over the next few years.

Autonomous Vehicles and ML Integration in Logistics

While fully autonomous vehicles are still being deployed carefully, the ML that powers them will become fully integrated into fleet management. ML systems will manage both human-driven and autonomous vehicles seamlessly on the same platform. Forward-thinking logistics companies are already exploring generative AI integration services to create conversational interfaces that allow dispatchers to communicate naturally with autonomous fleet management systems.

Edge Computing for Real-Time Logistics Decisions

Instead of sending all sensor data to the cloud for processing, ML models will increasingly run on devices at the “edge”, on the truck, on the warehouse robot. This enables lightning-fast, real-time decisions, which are critical for safety and speed.

ML for Supply Chain Sustainability Optimization

As companies face greater regulatory and consumer pressure, ML will move beyond cost savings to focus on environmental impact. Models will optimize shipping modes and routes specifically to minimize carbon emissions, making ML a key driver of green logistics.

Achieving End-to-End Supply Chain Visibility with AI

The ultimate goal is a single, unified view of every asset, shipment, and transaction across the entire globe. AI in Logistics will fuse data from hundreds of sources like carriers, customs, suppliers, and internal systems, to provide true, granular end-to-end supply chain visibility, allowing for proactive risk mitigation at every stage.

Why Choose CMARIX for Machine Learning App Development

CMARIX helps logistics and supply chain companies unlock real ROI with custom machine learning solutions. As a leading logistics software development company, we deliver high expertise in predictive analytics, warehouse automation, and route optimization, offering end-to-end ML development.

Our experts build scalable, cloud-enabled AI systems that optimize operations, reduce costs, and improve decision-making. Collaborating with CMARIX makes sure innovation, agility, and measurable business impact.

Concluding Lines

The logistics sector of 2025 will reward the flexible, resilient, and efficient. Machine learning is now considered a fundamental tool for growth and survival. By prioritizing the adoption, supply chain and logistics companies can transform complex challenges into competitive advantages and build a more profitable and predictable future.

Frequently Asked Questions on Machine Learning in Logistics

How is AI being used in logistics?

AI is used for real-time decision-making, including demand forecasting, automated warehouse operations (picking/sorting), and predictive maintenance for transportation fleets. It processes large datasets to generate actionable insights that surpass human capability.

How machine learning is transforming supply chain and logistics management?

ML transforms logistics by shifting operations from reactive to predictive, optimizing resource allocation (inventory, fleet capacity), and automating complex, error-prone tasks like data entry and route planning. This drastically increases efficiency and resilience.

Can machine learning help optimize delivery routes?

Yes, ML is essential for route optimization. It analyzes real-time traffic, weather, driver hours, and delivery time windows to dynamically calculate the most fuel- and time-efficient paths for last-mile delivery.

How will emerging technologies like generative AI or IoT impact logistics?

IoT provides the immense, real-time data stream (telematics, sensor data) necessary to train ML models, while Generative AI may soon be used to automate complex administrative tasks like drafting customs documentation or customer service responses.

Why do we use logistic regression in machine learning?

Logistic regression is used in machine learning for classification problems, such as predicting binary outcomes like “Will this equipment fail (Yes/No)?” or “Is this a fraudulent transaction (Yes/No)?” in logistics risk assessment.